The 2026 Complete Guide to Pool and Outdoor Living Structural Engineering in TX, NC, & FL

- JRH Engineering & Environmental Services, Inc.

- 2 hours ago

- 11 min read

Transform your backyard into a luxury retreat—but only if it's engineered right. From gunite pools withstanding 180 mph hurricane winds in Miami to outdoor kitchens engineered for expansive Texas clay to mountain-region patio covers designed for North Carolina snow loads, pool and outdoor living structures demand specialized structural engineering that most general contractors simply cannot provide.

JRH Engineering & Environmental Services is the premier provider of Civil Engineering and Structural Engineering Design Solutions in the states of Texas, North Carolina, and Florida. Our licensed Professional Engineers understand the unique code requirements, soil challenges, and climate demands of each region—delivering pool and outdoor living designs that pass inspection the first time, withstand decades of use, and reflect our unwavering commitment: "Done Quickly. Done Right. And for the Best Value."

Why Professional Structural Engineering Is Non-Negotiable for Pools and Outdoor Living

Building a pool or outdoor kitchen without professional structural engineering isn't just risky—it's often illegal. Municipal building departments across Texas, North Carolina, and Florida require sealed engineering plans from licensed Professional Engineers before issuing construction permits. This requirement exists because pools and outdoor structures face extraordinary structural demands that untrained designers cannot adequately address.

The Critical Role of Structural Engineers in Pool Projects

Structural engineers ensure your pool can withstand forces that would destroy improperly designed structures:

Hydrostatic Pressure: Water weighs 62.4 pounds per cubic foot. A modest 400-square-foot pool containing 15,000 gallons exerts over 125,000 pounds of outward pressure on its walls. Engineers calculate precise shell thickness and reinforcement to resist these forces.

Soil Pressure: When a pool is empty (required periodically for maintenance), surrounding soil exerts tremendous inward pressure. Properly engineered concrete pools can stand empty indefinitely; improperly designed pools collapse.

Groundwater Uplift: High water tables can literally "float" an empty pool out of the ground. Engineers design hydrostatic relief systems and calculate the ballast required to prevent flotation.

Adjacent Structure Surcharges: Pools built near homes, retaining walls, or outdoor kitchens must account for the additional loads these structures impose. Engineers analyze these interaction forces and design appropriate reinforcement.

Professional structural engineering transforms a pool from a potential liability into a decades-long asset. JRH's engineers bring the site-specific analysis, code expertise, and construction oversight that protect your substantial investment.

2026 Pool Structural Engineering Guide: State-by-State Requirements

Understanding regional engineering requirements helps you budget accurately and avoid costly permit rejections. Here's what professional pool engineering costs and delivers in each state.

Texas Pool Structural Engineering Requirements

Texas presents unique challenges from expansive clay soils to coastal windstorm insurance requirements.

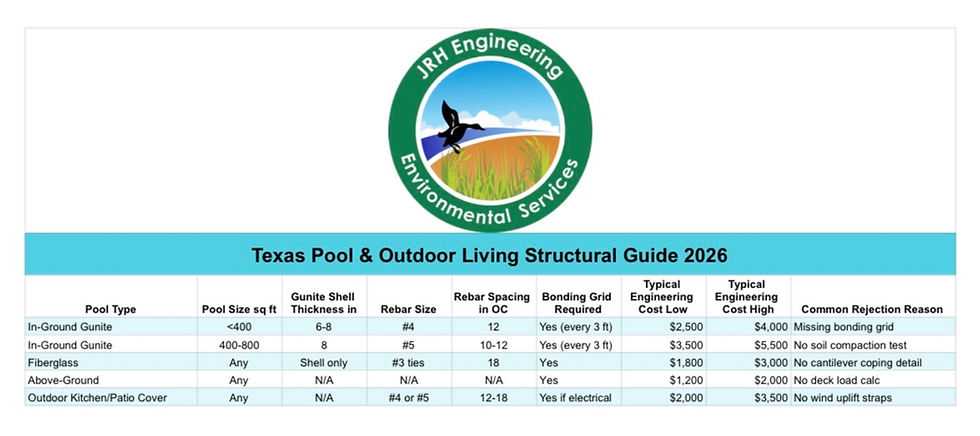

Texas Pool Engineering Specifications:

Texas-Specific Engineering Considerations:

The Dallas-Fort Worth, Houston, and Austin metropolitan areas sit atop highly expansive clay soils that can generate uplift pressures exceeding 10,000 pounds per square foot. Pool engineers must account for this extreme soil movement in their designs. Additionally, coastal pools within the Texas Department of Insurance (TDI) windstorm zone require engineering that facilitates WPI-8 certification for windstorm insurance eligibility.

JRH's Texas pool engineers design foundations that accommodate soil expansion while meeting TDI wind load requirements—a combination of expertise that generic pool builders lack.

North Carolina Pool Structural Engineering Requirements

North Carolina's geographic diversity—from sea-level coastal plains to 6,000-foot mountain elevations—creates widely varying engineering requirements.

North Carolina Pool Engineering Specifications:

North Carolina Regional Variations:

Coastal Outer Banks projects face 130-150 mph wind design requirements and must achieve Fortified Home certification for insurance benefits. Mountain region pools in counties like Watauga, Avery, and Mitchell require frost footings extending 12-18 inches below grade and snow load calculations for patio covers—requirements that coastal engineers often overlook.

JRH's North Carolina team understands these regional nuances and designs accordingly, eliminating the permit rejections that plague out-of-state engineering firms.

Florida Pool Structural Engineering Requirements

Florida imposes the nation's most stringent pool engineering standards, particularly in High-Velocity Hurricane Zones (HVHZ) covering Miami-Dade and Broward counties.

Florida Pool Engineering Specifications:

Florida's Unique Engineering Requirements:

Coastal Florida pools must often be designed on deep pile foundations extending through sandy soils to competent bearing strata. ASCE 24 Section 9.6 requires pools in flood zones to resist flood forces, be designed to break away, or be elevated based on site-specific engineering. Pool equipment must be elevated "to the extent practical" and anchored to prevent flotation during storm surge events.

Screen enclosures surrounding pools in HVHZ areas require Miami-Dade Notice of Acceptance (NOA) product approvals and engineering that accounts for wind flowing through the porous screen material—fundamentally different from solid building wind loads.

JRH's Florida pool engineering expertise navigates these complex requirements efficiently, ensuring your project passes the state's rigorous inspections.

Understanding Gunite Pool Structural Design

Gunite (also called shotcrete) represents the gold standard in pool construction due to its strength, flexibility, and longevity. Understanding the structural engineering behind gunite pools helps you appreciate why professional design is essential.

The Anatomy of an Engineered Gunite Pool

A properly engineered gunite pool consists of multiple integrated structural systems:

Steel Rebar Framework: The structural skeleton typically uses 1/2-inch 8-gauge steel rebar spaced 8-12 inches on center throughout the pool shell. Premium builders use 8-inch spacing; budget builders use 12-inch spacing. This steel grid provides tensile strength that concrete lacks.

Gunite Shell Application: A pneumatic spraying process propels a cement-sand mixture at high velocity onto the rebar framework. Proper application achieves 4,000+ psi compressive strength and creates an 8-10 inch thick monolithic shell.

Structural Tie System: Engineers specify how the pool shell connects to surrounding decking, equipment pads, and adjacent structures. These tie details prevent differential settlement and structural separation.

Drainage and Pressure Relief: Hydrostatic relief valves and drainage stone layers prevent groundwater from floating the empty pool. Engineers calculate when these systems are required based on local water table data.

Why Custom Engineering Beats "Standard" Pool Plans

While some pool builders offer "standard" engineering packages, these generic plans cannot account for your site's specific conditions. Every property presents unique challenges:

Soil composition varies dramatically—even within the same neighborhood

Groundwater levels fluctuate seasonally

Adjacent structures impose different load patterns

Local building code amendments modify base requirements

JRH's site-specific engineering approach analyzes your exact conditions through geotechnical investigation, surveys the surrounding structures, and designs reinforcement precisely calibrated to your project's needs—not a generic "one-size-fits-all" solution.

Equipotential Bonding: The Critical Safety System Most Builders Overlook

Permit rejections for "missing equipotential bonding" top the list across all three states. This electrical safety system is mandated by the National Electrical Code (NEC) Article 680.26 but is frequently misunderstood or improperly installed.

What Is Equipotential Bonding?

Equipotential bonding creates a zone around your pool where no dangerous voltage differences can develop between objects swimmers might touch simultaneously. By electrically connecting all metallic components, the system ensures that even if an electrical fault occurs, current flows through bonding conductors rather than through a person in the pool.

NEC Requirements for Pool Bonding

The National Electrical Code mandates bonding of all the following using #8 AWG solid copper conductor minimum:

Structural steel in the pool shell (rebar)

Metal pool components: ladders, handrails, diving board stands, light niches

Pool equipment: pump motors, heaters, pool covers

Metal within 5 feet horizontally of the pool's inside walls

Metal within 12 feet vertically above pool surfaces

Perimeter surfaces: The bonding grid must extend 3 feet beyond the pool under concrete decking

Pool water itself: Must contact a 9-square-inch corrosion-resistant conductive surface

Common Bonding Mistakes That Fail Inspection

JRH's engineers see these recurring bonding errors that result in permit rejections:

Incomplete bonding grid: Failing to extend the grid 3 feet beyond the pool perimeter

Wrong conductor type: Using stranded wire instead of solid conductor, or undersized wire

Missing pool water bond: Not providing the required conductive contact with pool water

Inadequate connections: Poor mechanical connections that will corrode over time

Confusion with grounding: Bonding and grounding serve different purposes; both are required but must be implemented correctly

JRH's pool engineering plans include detailed bonding schematics that specify exact connection points, conductor routing, and installation procedures—ensuring inspectors approve your installation without costly rework.

Outdoor Kitchen and Patio Cover Structural Engineering

The outdoor living trend continues accelerating into 2026, with homeowners investing heavily in outdoor kitchens, covered patios, and multifunctional entertainment spaces. These structures require the same engineering rigor as pools—yet many are built without proper structural design, leading to failures.

2026 Outdoor Living Space Trends

Current design trends emphasize year-round usability and seamless indoor-outdoor integration:

Bioclimatic pergolas with motorized louvers for sun/rain control

Fully equipped outdoor kitchens with built-in grills, refrigerators, and pizza ovens

Smart technology integration including automated lighting, sound systems, and climate control

Covered pavilions and gazebos providing all-weather protection

Multi-functional zones for cooking, dining, lounging, and entertainment

While these features create stunning outdoor spaces, each introduces structural challenges that require professional engineering.

Engineering Requirements for Outdoor Kitchens

Outdoor kitchens present unique structural demands:

Foundation Design: Kitchen islands built on expansive clay soils require properly designed foundations that accommodate soil movement without cracking the masonry veneer

Lateral Bracing: Tall structures catch significant wind loads and require adequate bracing against lateral forces

Live Load Capacity: Countertops must support heavy equipment, stored items, and people leaning on surfaces—requiring adequate structural support

Utility Integration: Gas lines, electrical service, water supply, and drainage must be properly engineered and code-compliant

Patio Cover Wind Load Engineering

Patio covers and pergolas are particularly vulnerable to wind uplift forces. Proper engineering accounts for:

Design wind speeds: 120-180 mph depending on location and exposure

Roof configurations: Monoslope, gable, or hip roofs each generate different load patterns

Uplift resistance: Connection details must resist vertical uplift trying to tear the structure from its foundation

Lateral bracing: Preventing racking and collapse under horizontal wind pressures

Texas, North Carolina, and Florida each have specific wind load requirements that vary by region. JRH's engineers design patio covers using current ASCE 7 wind load provisions and state-specific building code amendments—ensuring your structure withstands local weather extremes.

Screen Enclosure Engineering: Specialized Wind Load Analysis

Pool screen enclosures are ubiquitous in Florida and increasingly popular in Texas and North Carolina coastal regions. These structures require specialized engineering that differs fundamentally from solid building design.

Why Screen Enclosures Are Different

Wind loads on screen enclosures develop through a different mechanism than solid structures. Wind flows through porous screens rather than around them, creating drag forces rather than pressure differentials. Screen mesh density dramatically affects wind loads:

Standard 18/14 mesh: 70% airflow, rated to 130 mph under optimal conditions

20/20 No-See-Um mesh: 65% airflow, rated to 140 mph

Super Screen 17/20: Maximum wind protection, rated 160+ mph

Load Cases for Screen Enclosure Design

Engineering standards require analysis of multiple load cases:

Load Case A: Pressure applied to the effective area of members directly supporting screen surfaces perpendicular to wind

Load Case B: Total drag force on the projected frontal area, transmitted through the structural system to the foundation

Flow-through vs. non-flow-through conditions: Different pressure applications depending on configuration

Florida HVHZ Screen Enclosure Requirements

Screen enclosures in Florida's High-Velocity Hurricane Zones face the strictest requirements:

Miami-Dade NOA required: Products must have valid Notice of Acceptance approvals

Enhanced inspection protocols: Third-party inspections verify compliance

Installation must match approved drawings exactly: Deviations void the approval

JRH's Florida engineers design screen enclosures with valid product approvals, complete structural calculations, and installation details that pass Miami-Dade inspections—avoiding the rejections that plague projects using out-of-state engineers.

Common Permit Rejection Reasons and How JRH Prevents Them

Building departments reject pool and outdoor living permits for recurring reasons. Understanding these common deficiencies—and how JRH prevents them—demonstrates the value of experienced engineering.

Texas Common Rejections

Missing bonding grid details: Incomplete equipotential bonding schematics

No soil compaction testing: Failing to specify compaction requirements for backfill

Inadequate wind uplift details: Missing tie-down specifications for patio covers

No deck load calculations: Failing to analyze deck live loads and cantilevers

North Carolina Common Rejections

Missing equipotential bonding: Incomplete NEC Article 680.26 compliance

Insufficient frost protection: Footings not extending below frost depth in mountain counties

No backfill compaction specifications: Lacking proper soil placement details

Missing snow load analysis: Mountain region structures lacking snow load calculations

Florida Common Rejections

Missing wind load calculations: Inadequate ASCE 7 wind analysis

No product approvals: Screen enclosures lacking Florida Product Approval or Miami-Dade NOA

No HVHZ wind design: Failing to meet High-Velocity Hurricane Zone requirements

Barrier non-compliance: Pool barriers not meeting Florida Building Code Section 454

No impact-rated openings: HVHZ structures lacking impact protection specifications

JRH's engineering process systematically addresses each potential rejection reason before plan submission. Our engineers know exactly what each building department requires and provide complete, code-compliant documentation that passes review the first time.

Frequently Asked Questions: Pool & Outdoor Living Engineering

Do I really need an engineer for a simple above-ground pool?

Yes. Even above-ground pools require engineering for deck design, load calculations, and electrical bonding systems. Building departments will not issue permits without sealed engineering plans from a licensed Professional Engineer. Attempting to build without proper engineering risks permit denial, construction stops, costly rework, and potential liability if someone is injured.

What's the difference between standard and special pool engineering?

Standard pool engineering covers basic structural requirements: shell thickness, rebar spacing, bonding grid, and foundation design for typical site conditions. Special engineering addresses unique challenges like:

Pools on slopes requiring retaining walls

Properties with high groundwater requiring dewatering systems

Custom features like infinity edges, grottos, or attached spas

Sites with poor soil requiring deep foundation systems

JRH provides both standard and special engineering, tailoring our approach to your project's specific needs.

How long does the pool engineering and permitting process take?

Timeline varies by jurisdiction and project complexity:

Engineering design: 2-4 weeks after receiving survey and geotechnical data

Permit review: 2-8 weeks depending on municipality

Plan revisions (if needed): 1-2 weeks per cycle

JRH's experience with building departments across Texas, North Carolina, and Florida accelerates this timeline. Our plans are submitted complete and code-compliant, minimizing review cycles and getting you to construction faster.

Why Developers, Contractors, and Property Owners Choose JRH

Done Quickly.

Time costs money. Every week spent in permitting review delays your project's completion and pushes back your ability to enjoy (or monetize) the investment. JRH's engineers know exactly what each building department requires. Our plans arrive complete, organized, and code-compliant—passing review on the first submission and eliminating the weeks of delay that plague projects using inexperienced firms.

Done Right.

Structural failures are catastrophic. Pool shell cracks, deck settlement, patio cover collapse, and electrical hazards create liability exposure that far exceeds any engineering cost savings. JRH's licensed Professional Engineers bring decades of combined experience in pool and outdoor living structural design. We perform site-specific analysis, calculate loads precisely, and detail connections properly—ensuring your structure performs safely throughout its design life.

And for the Best Value.

Value engineering is our standard practice, not an afterthought. We analyze multiple design alternatives, identify cost-effective materials that meet performance requirements, and eliminate unnecessary over-design that inflates construction costs. This optimization routinely saves clients 15-30% compared to generic engineering packages—while delivering superior performance and code compliance.

JRH's Three-State Expertise: Your Competitive Advantage

Operating across Texas, North Carolina, and Florida provides JRH with unique insights into regional differences and best practices. A solution that works perfectly in Dallas may fail catastrophically in Miami—and vice versa. Our multi-state experience allows us to:

Apply best practices across regions: Innovation developed in one state benefits clients in others

Navigate code variations efficiently: We understand how base codes are amended locally

Leverage relationships with building officials: Our reputation expedites permit reviews

Design for actual climate conditions: We engineer for real-world weather, not theoretical scenarios

Whether you're developing a luxury resort pool in Palm Beach, building a backyard oasis in Charlotte, or constructing a poolside outdoor kitchen in Austin, JRH Engineering delivers the regional expertise your project demands.

Ready to Start Your Pool or Outdoor Living Project?

Transform your outdoor space with confidence, knowing your investment is protected by professional structural engineering. From initial concept through final inspection, JRH Engineering partners with you to deliver pool and outdoor living spaces that exceed expectations—safely, efficiently, and cost-effectively.

JRH Engineering & Environmental Services is the premier provider of Civil Engineering and Structural Engineering Design Solutions in the states of Texas, North Carolina, and Florida. We live our commitment every day: "Done Quickly. Done Right. And for the Best Value."

Contact JRH today to schedule your free consultation. Our team is ready to discuss your project vision, answer your technical questions, and provide the expert engineering services that ensure your pool or outdoor living space becomes the backyard retreat you've always imagined.

Call us at (800) 227-9635 or visit www.jrhengineering.net to get started.

Comments